Please use our website in portrait format.

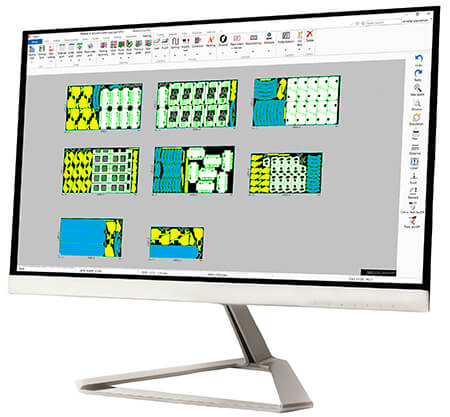

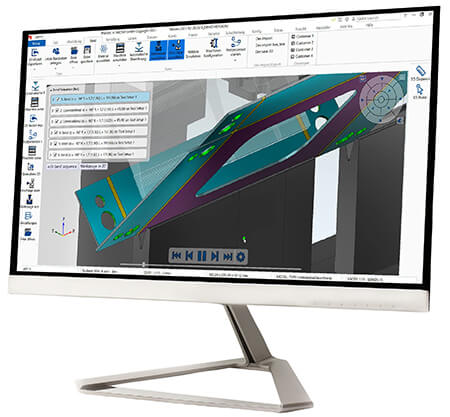

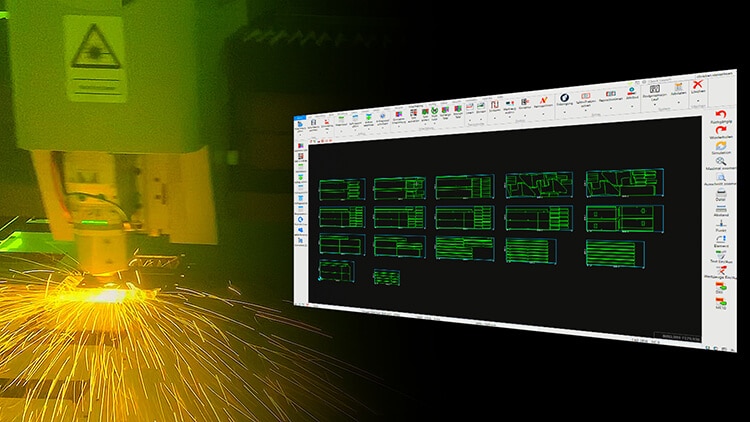

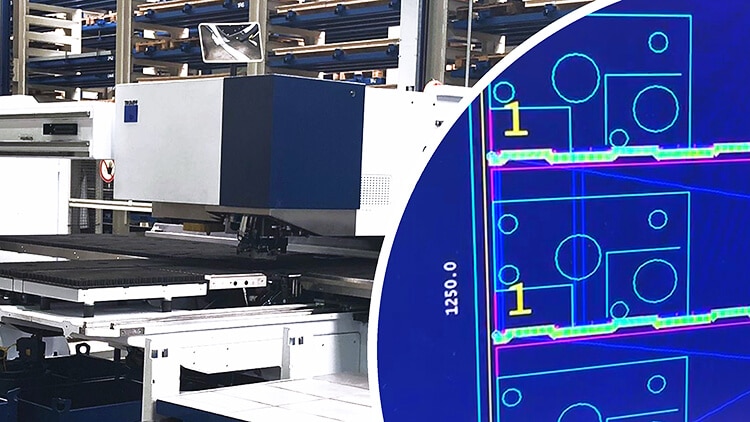

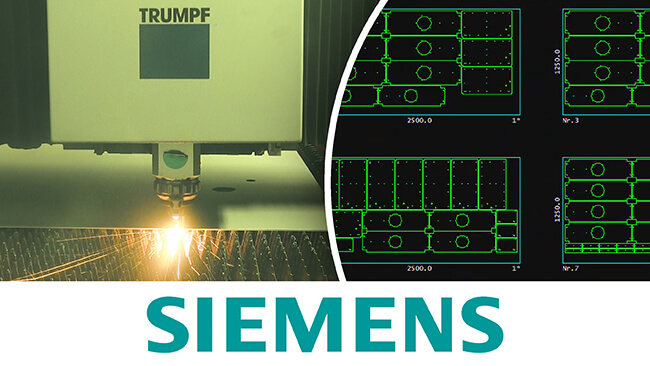

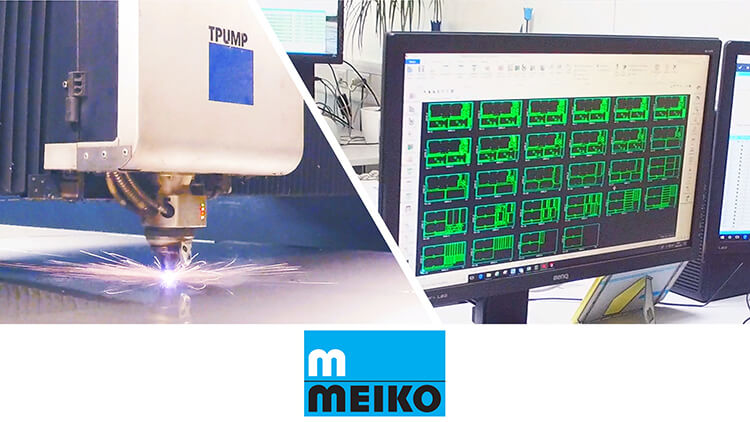

CAD/CAM System

PN4000

CAD/CAM System for ERP/PPS controlled CNC cutting, punching, shearing, milling and combined machining – manual to fully automatic.

Order Control

PNControl

Order management, detailed planning, production feedback and monitoring of deadlines and production.

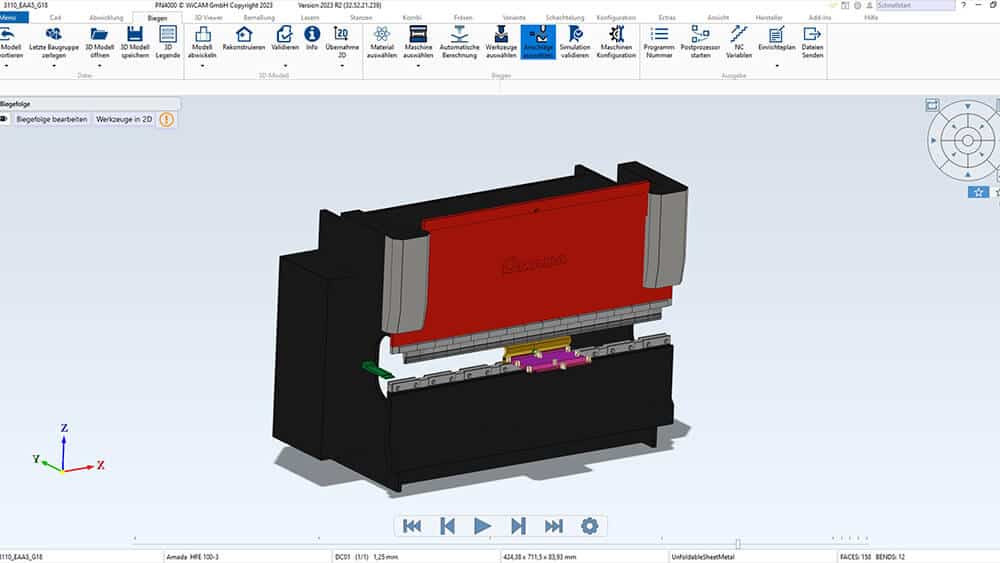

Bend Simulation

PNBend

Unfolding, bend simulation and offline programming of CNC press brakes from various manufacturers.

Calculation

PNCalculate

Online unfolding, calculation, CAD and NC format conversion, parametric component creation.

Training

Well developed and motivated employees are an important element in the daily competition.

Development

We develop new solutions to the very specific requirements for you.

Downloads

For our customers we offer updates and more files online.