We develop new solutions to the very specific requirements of the customer – individual and reliable. We offer tailor-made products – exactly as they are needed. We also modify existing software modules according to the particular requirements.

We develop new solutions to the very specific requirements of the customer – individual and reliable. We offer tailor-made products – exactly as they are needed. We also modify existing software modules according to the particular requirements.

Examples:

- Conversion of existing data

- Tailored connection to ERP-Systems

- Tailored connection to Storage-Systems

- Tailored connection to PDM-Systems

- Tailored connection to CAD-Systems

- Tailored functionality to optimize your processes

- Feedback of production data to your ERP-System

We are glad to advise you.

Began

Began

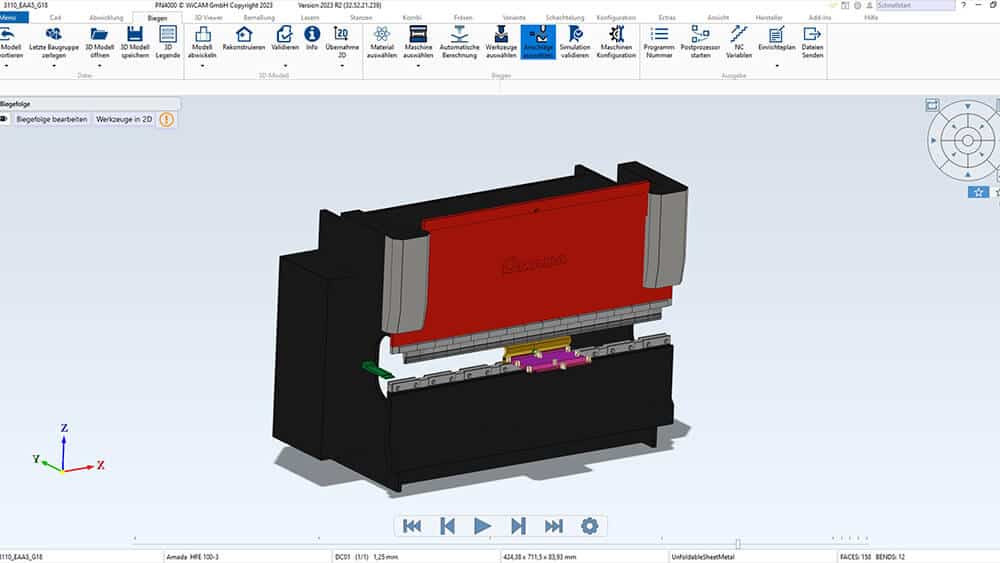

In retrospect, this graph looks like a forecast for the future that came true at the time. But for us, it is the key qualification for the success of WiCAM today.

Already in the 80’s, company founder “Harald Wilkesmann” had the vision to connect whole production factories worldwide. It was already clear to him then that machine control would only be a means to an end and that the challenge would be much more in process management.

With this clear vision, he started to program the first lines of code of today’s CAD/CAM system PN4000, which due to its design can be connected to any ERP/PPS system. In the past an absolute rarity, today exactly what the industry needs.

The development teams of WiCAM are specialized in exactly this and can connect almost every ERP system and its production with individual solutions.

We develop new solutions to the very specific requirements of the customer – individual and reliable. We offer tailor-made products – exactly as they are needed. We also modify existing software modules according to the particular requirements.

We develop new solutions to the very specific requirements of the customer – individual and reliable. We offer tailor-made products – exactly as they are needed. We also modify existing software modules according to the particular requirements.

Began

Began