Please use our website in portrait format.

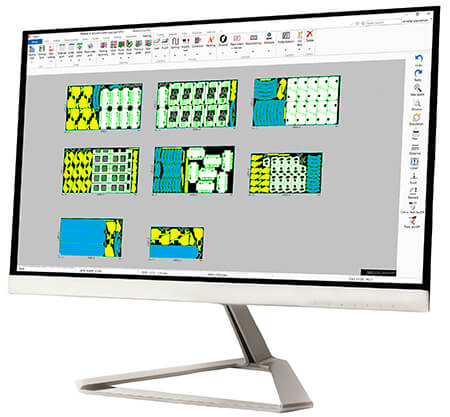

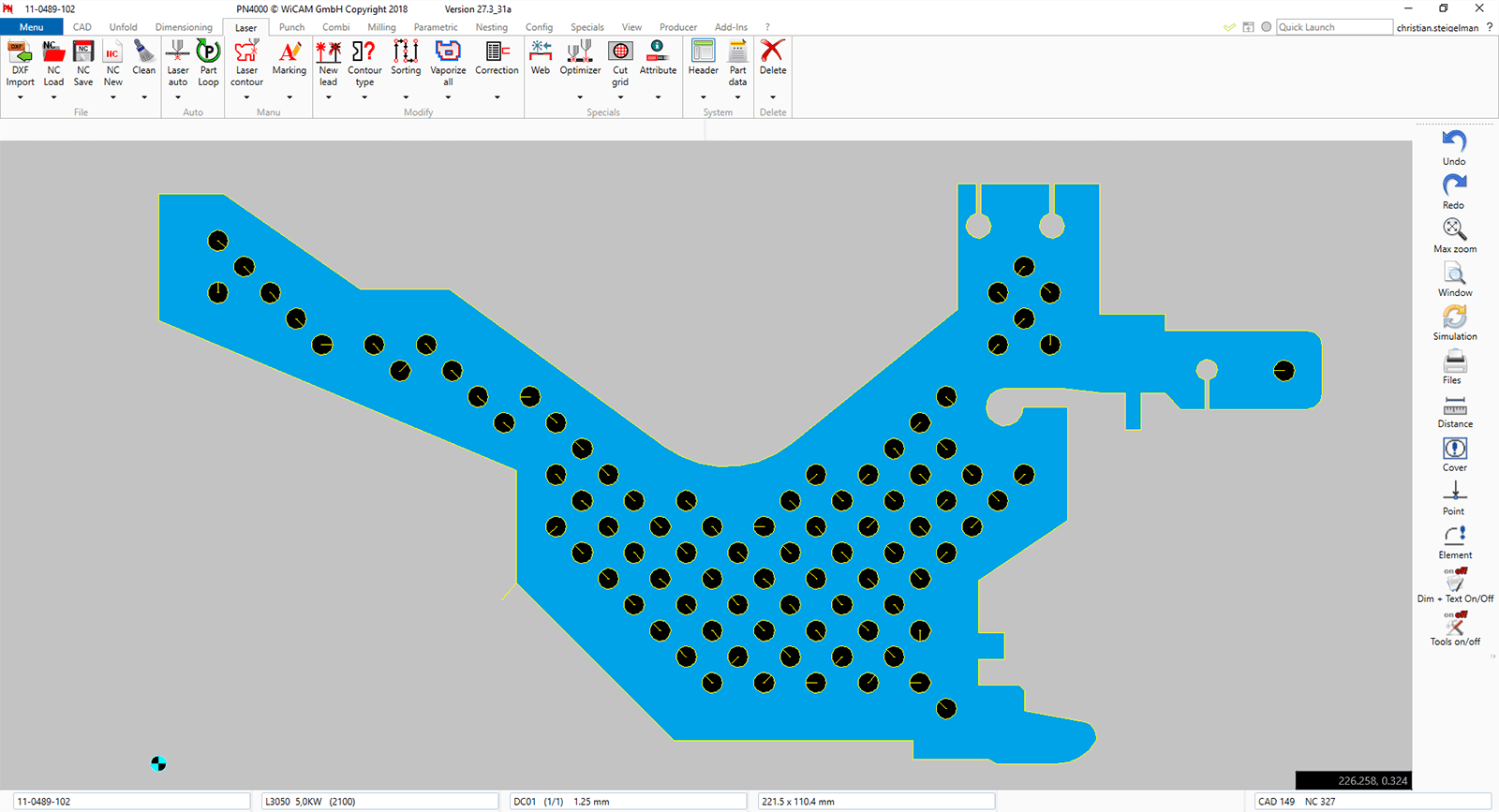

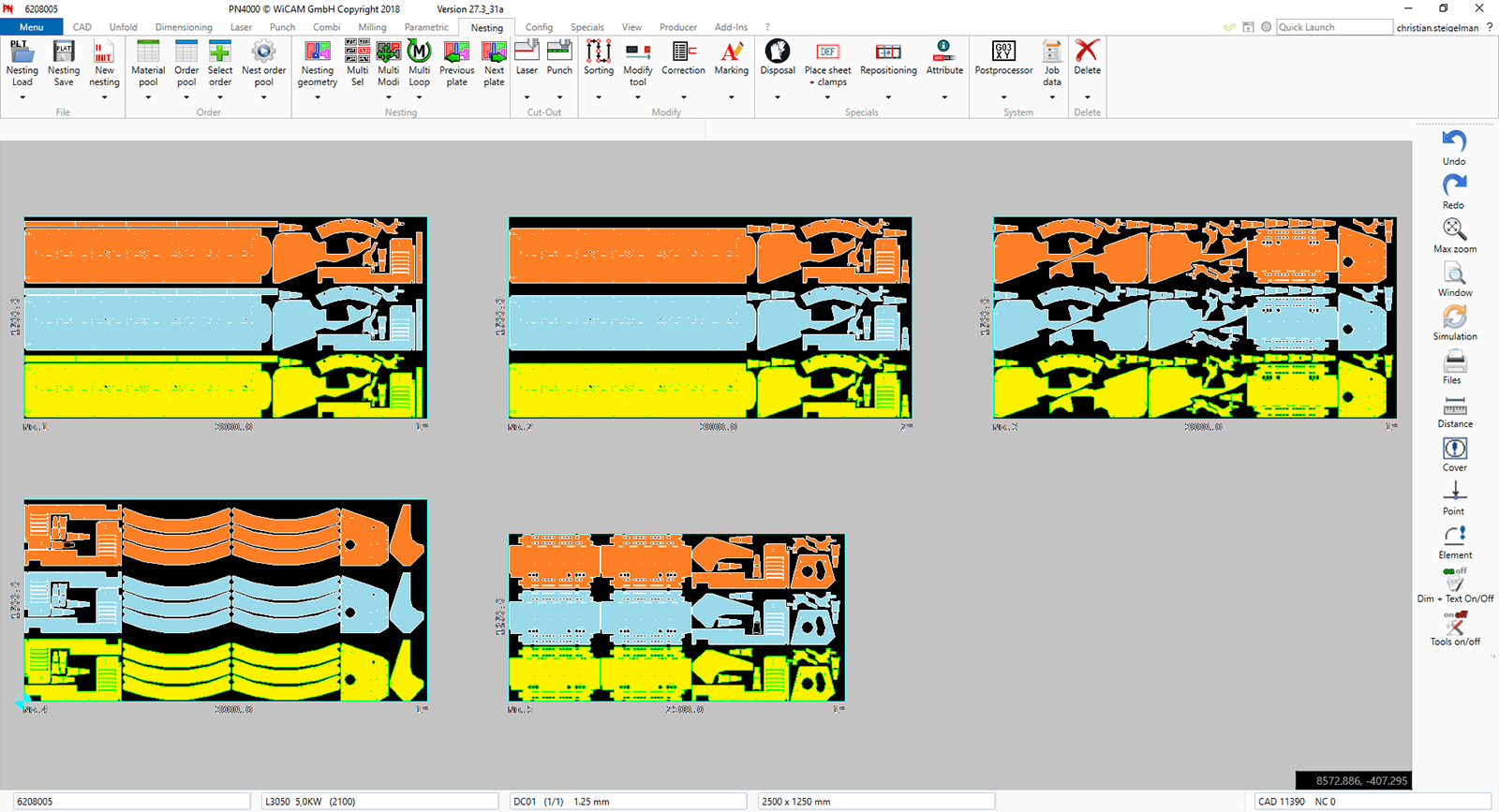

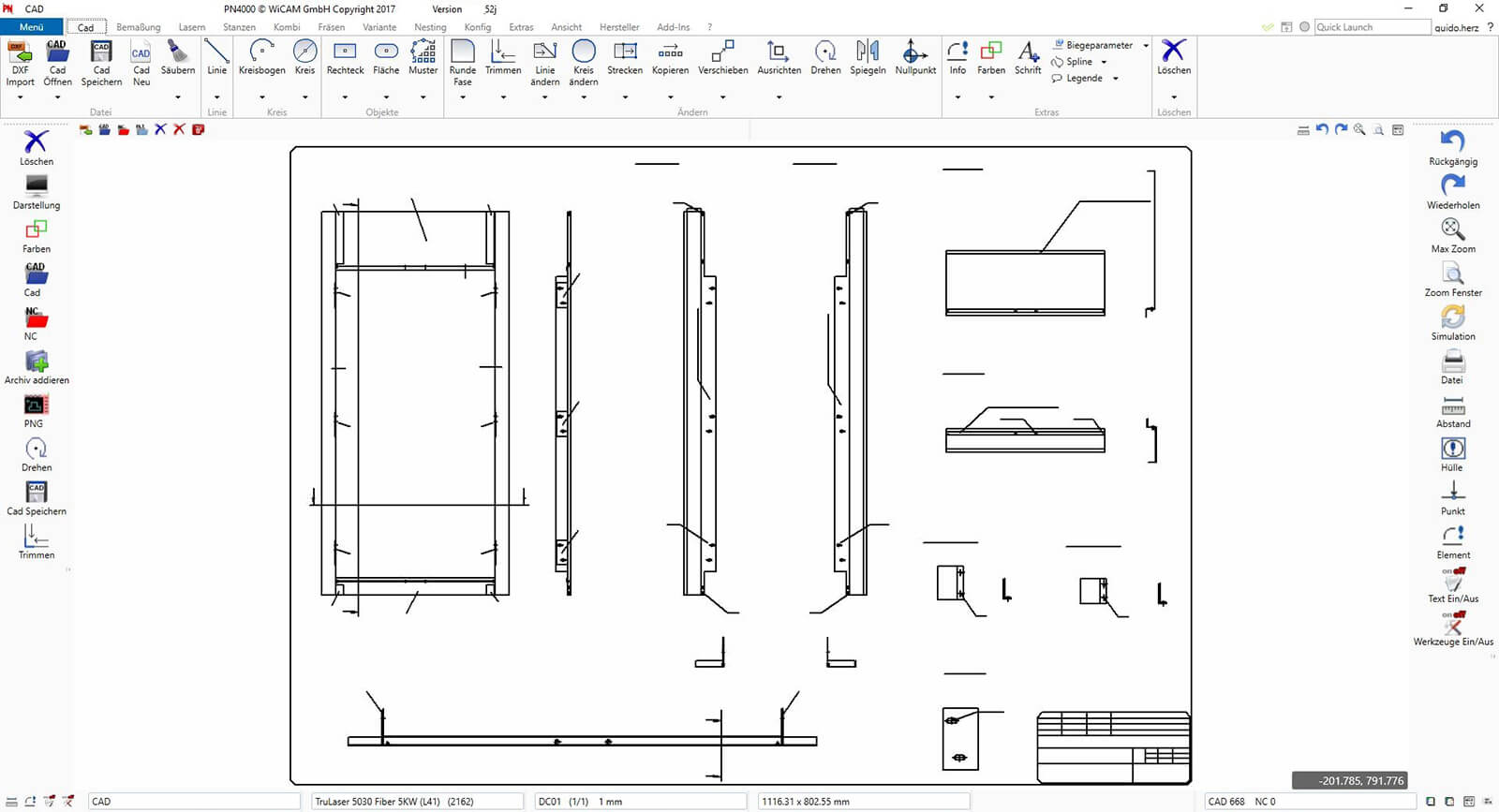

CAD/CAM System

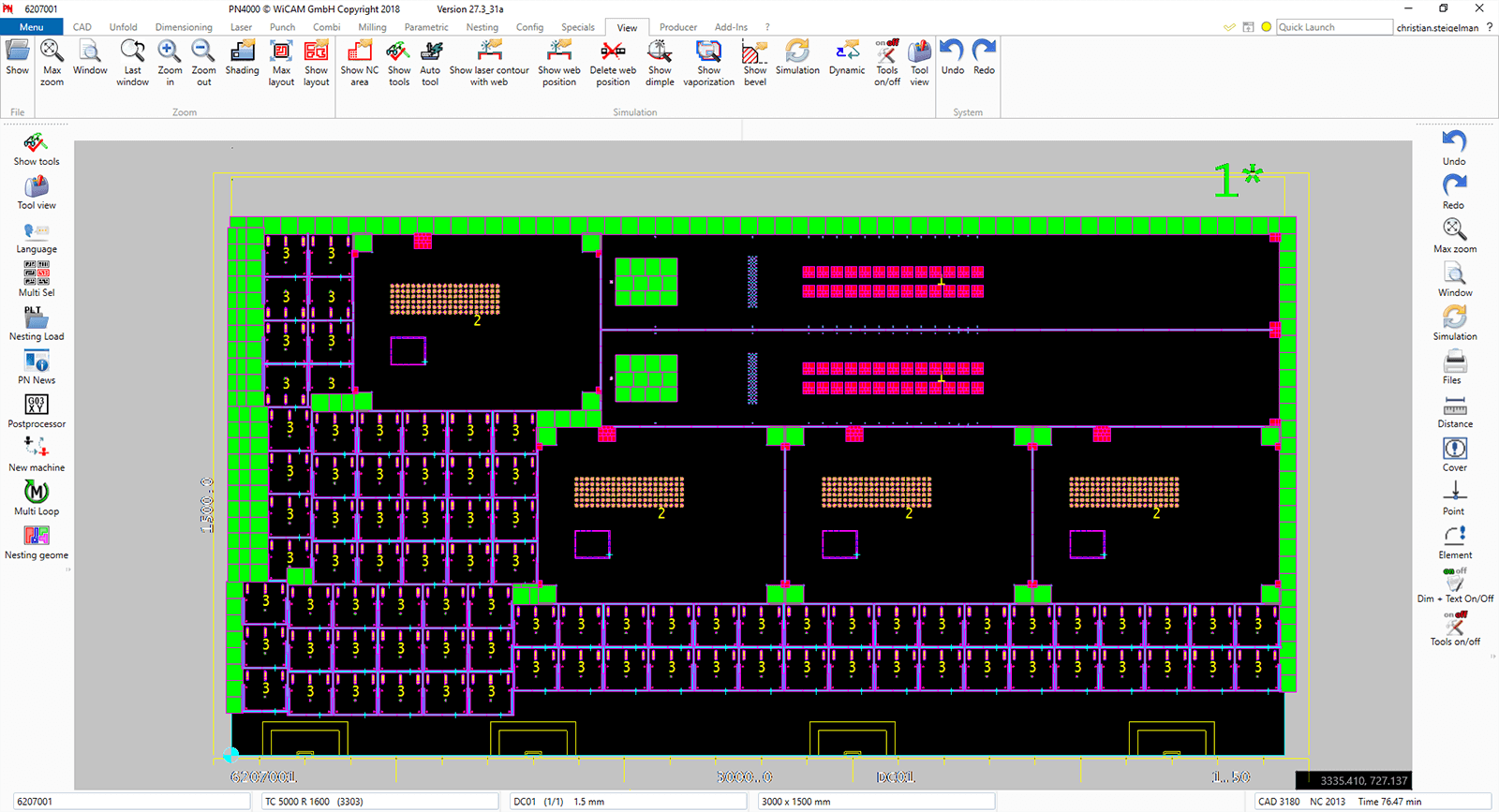

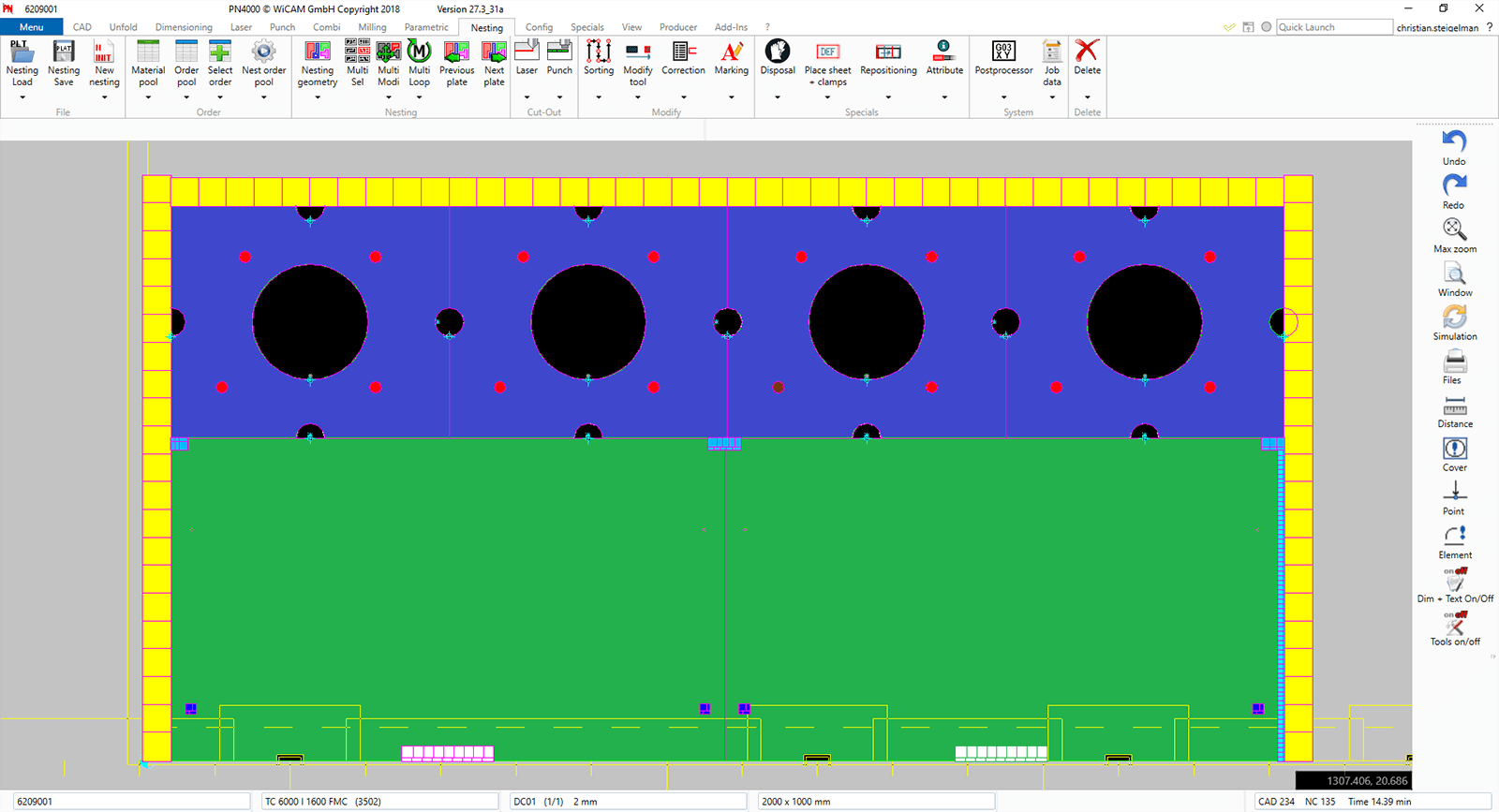

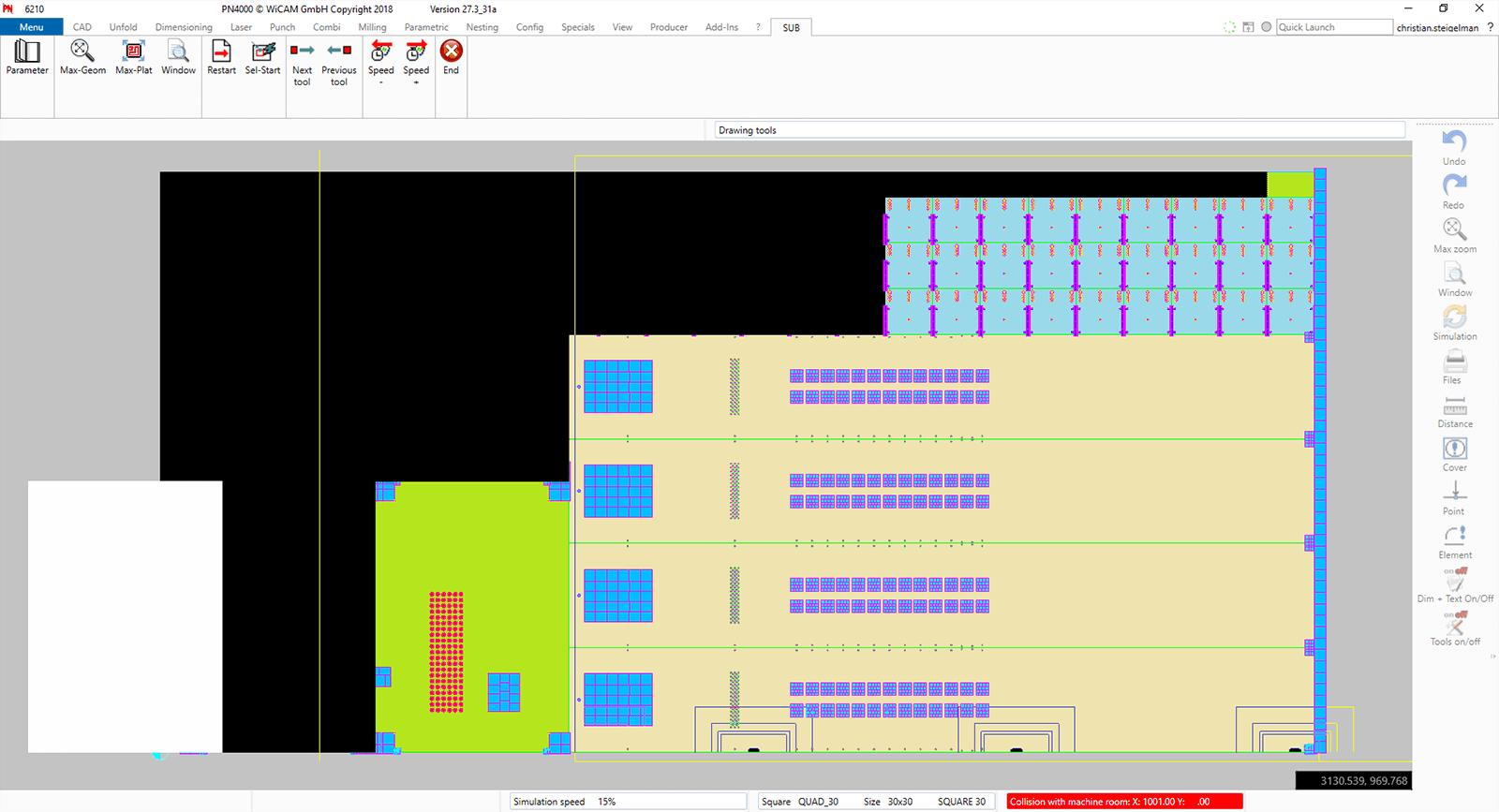

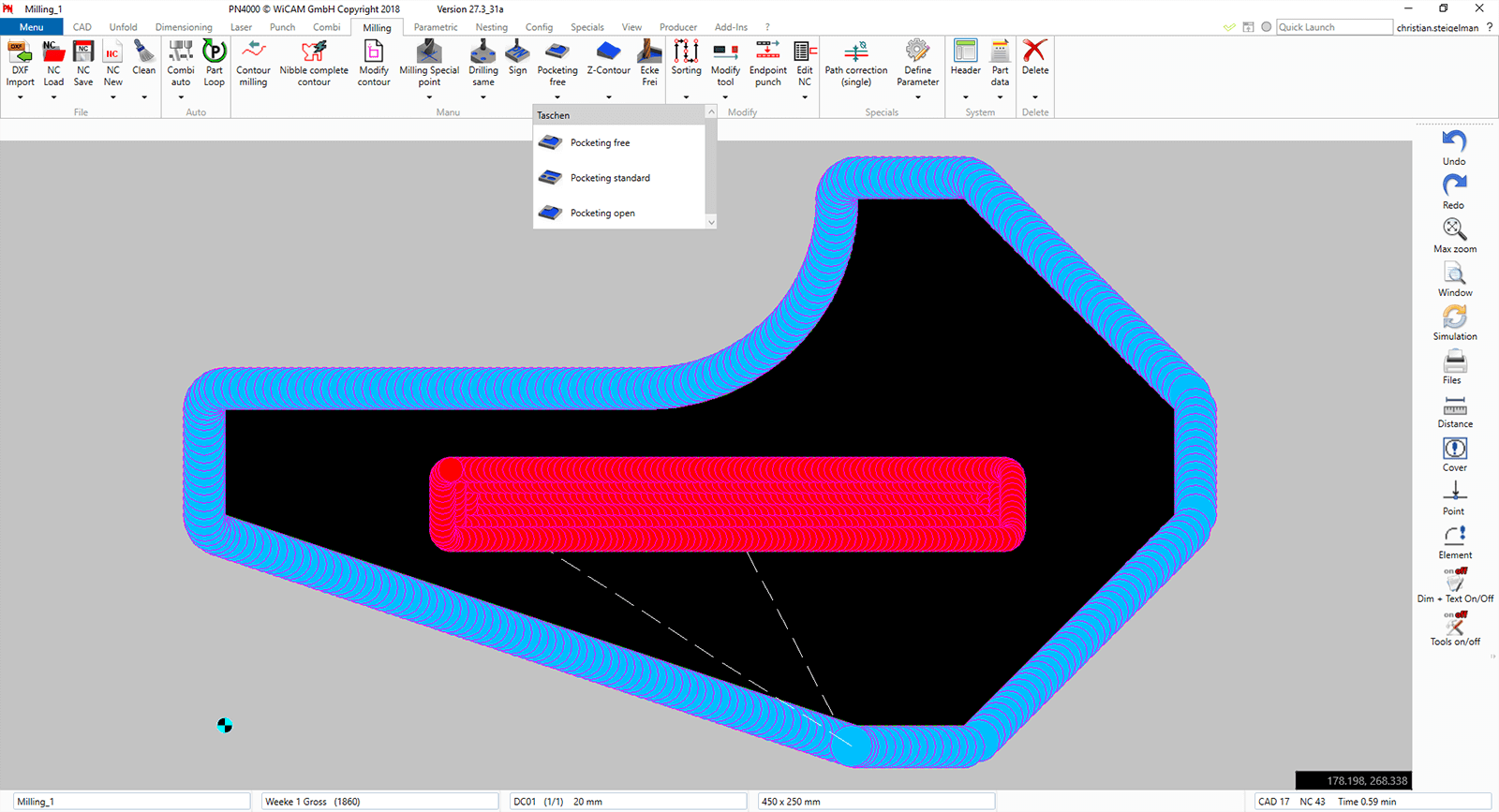

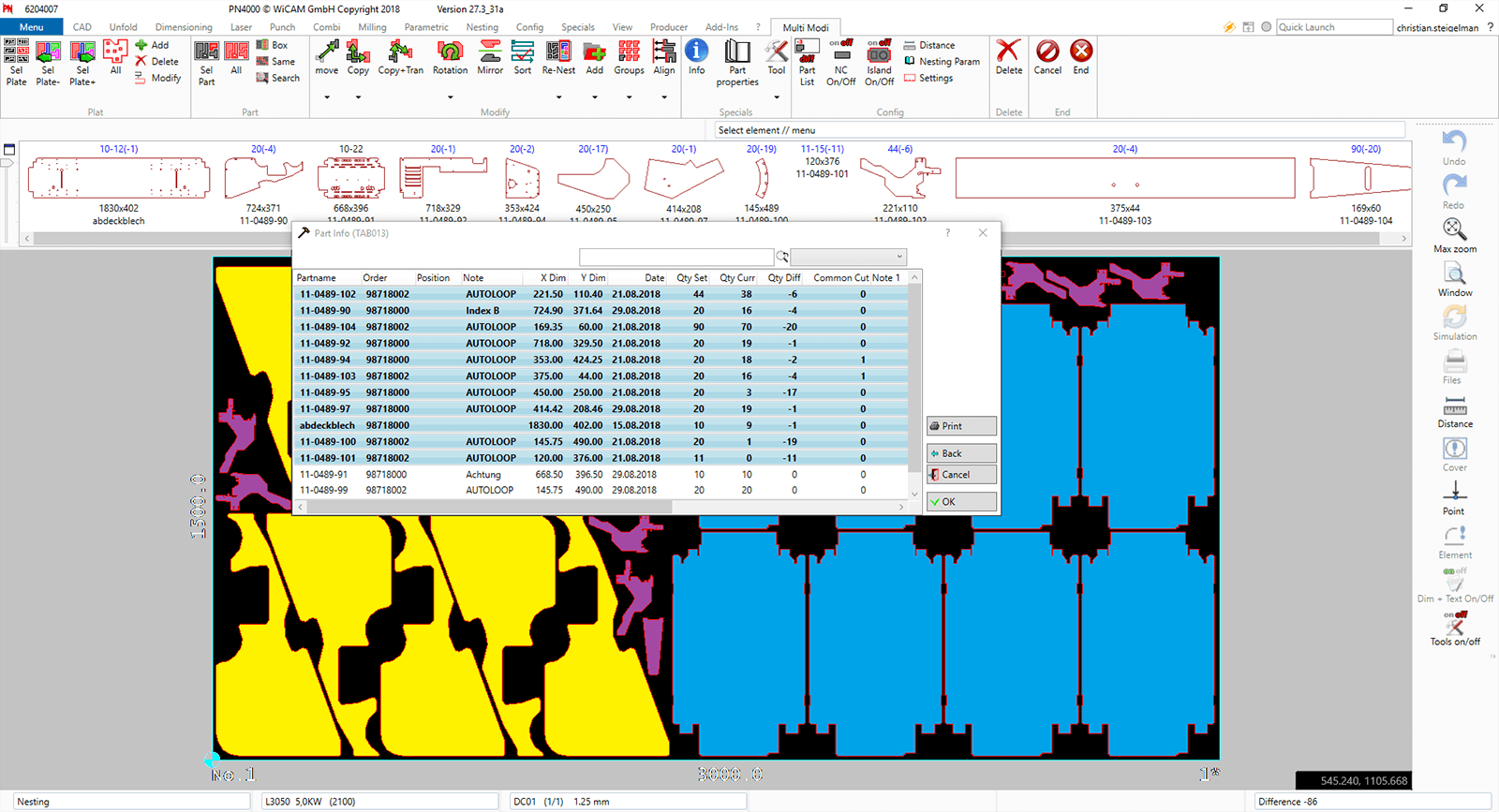

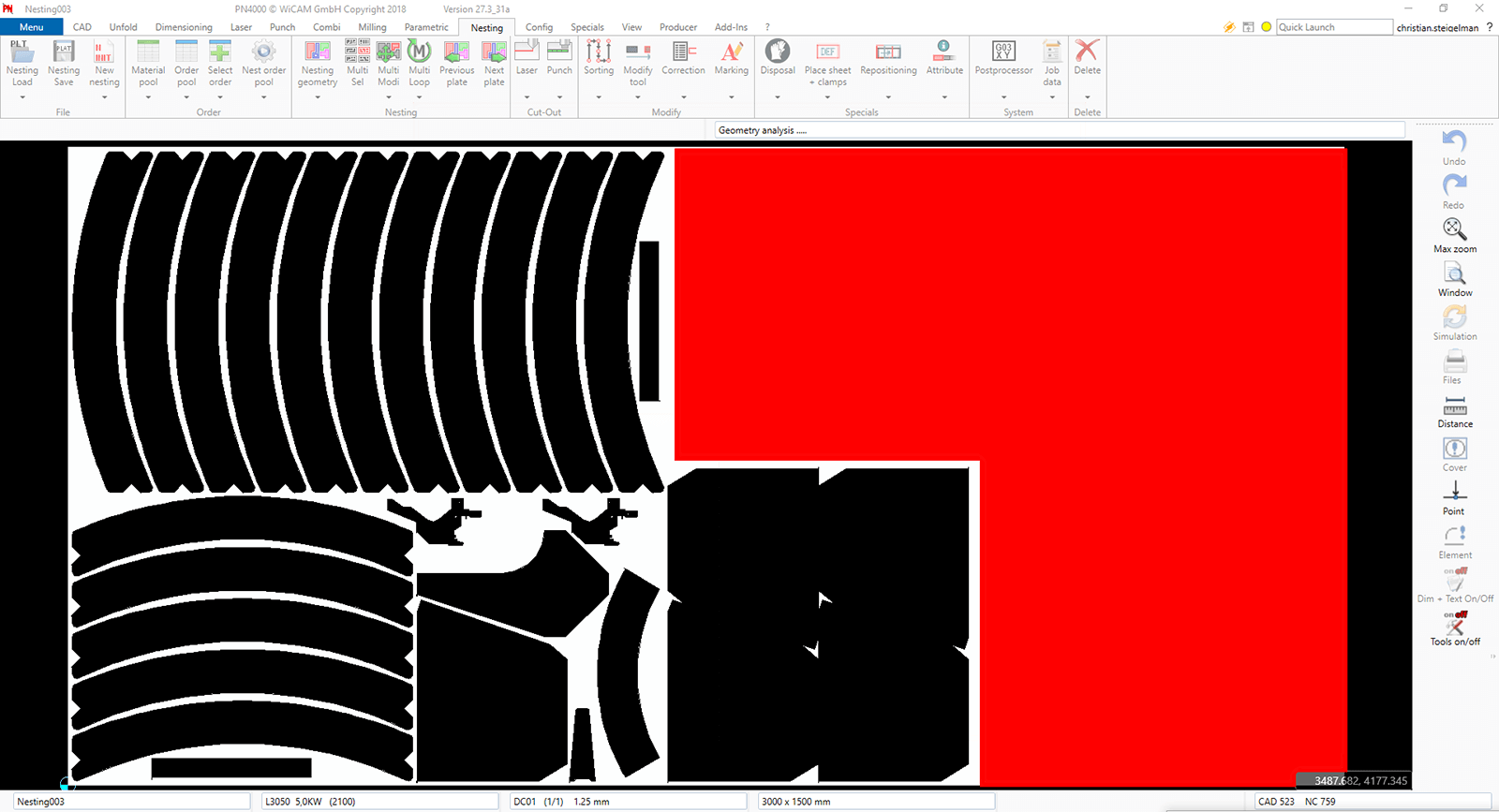

PN4000

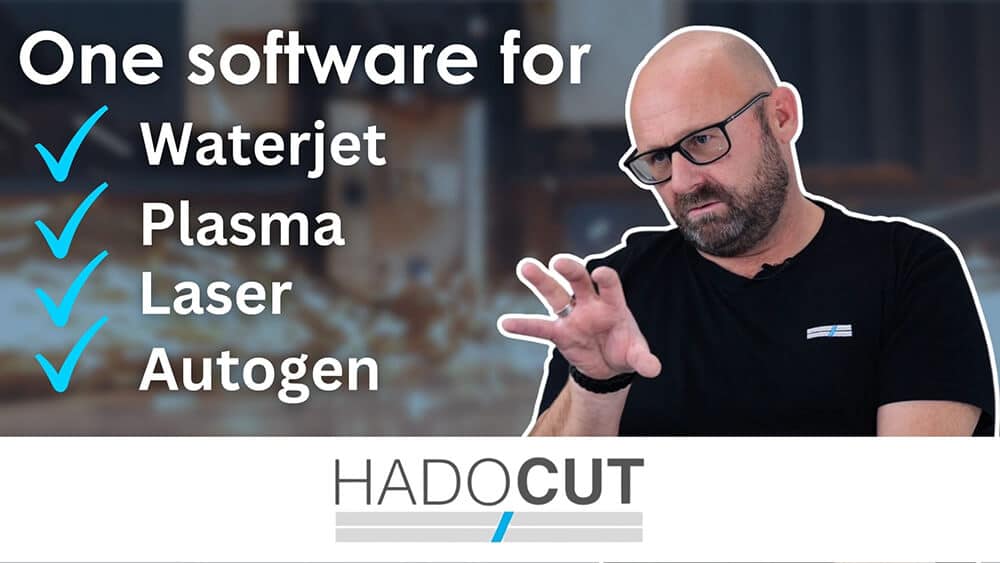

CAD/CAM System for ERP/PPS controlled CNC cutting, punching, shearing, milling and combined machining – manual to fully automatic.

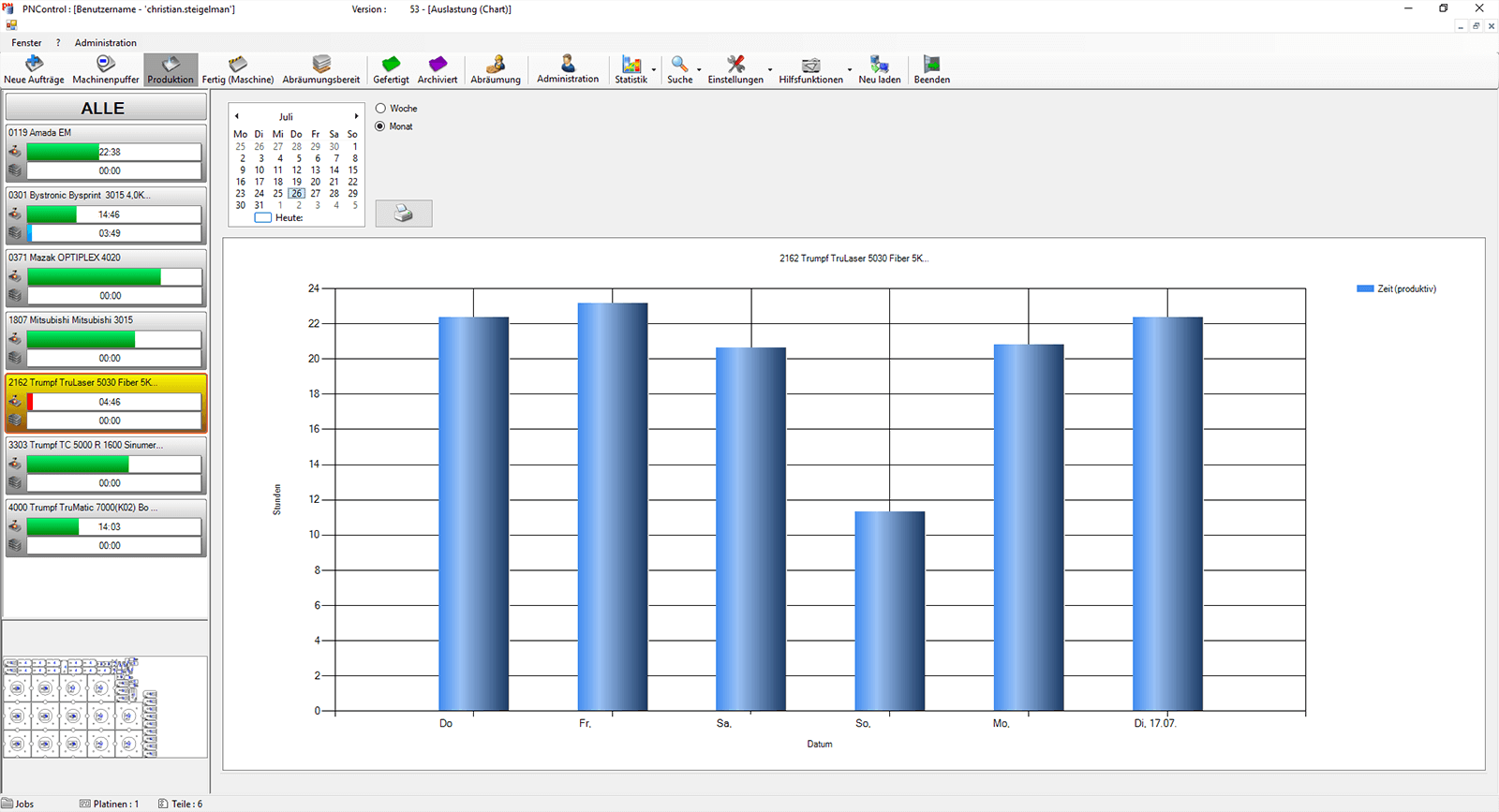

Order Control

PNControl

Order management, detailed planning, production feedback and monitoring of deadlines and production.

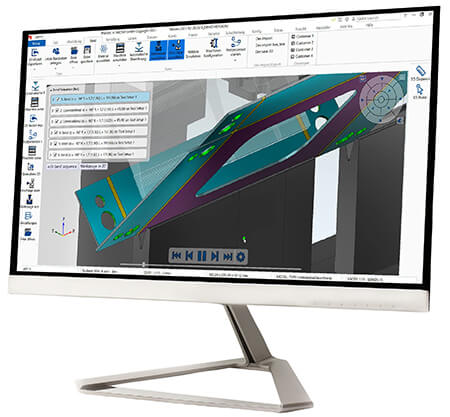

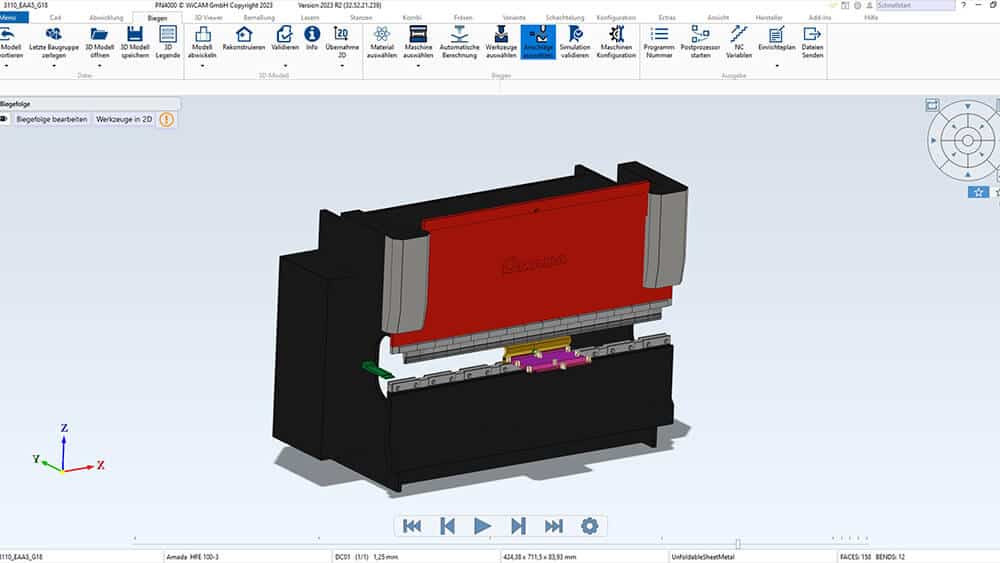

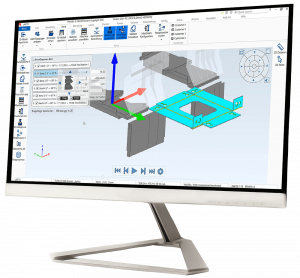

Bend Simulation

PNBend

Unfolding, bend simulation and offline programming of CNC press brakes from various manufacturers.

Calculation

PNCalculate

Online unfolding, calculation, CAD and NC format conversion, parametric component creation.

Training

Well developed and motivated employees are an important element in the daily competition.

Development

We develop new solutions to the very specific requirements for you.

Downloads

For our customers we offer updates and more files online.

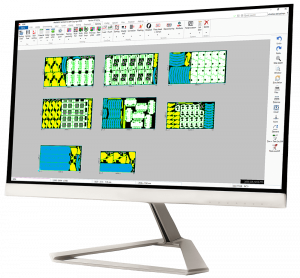

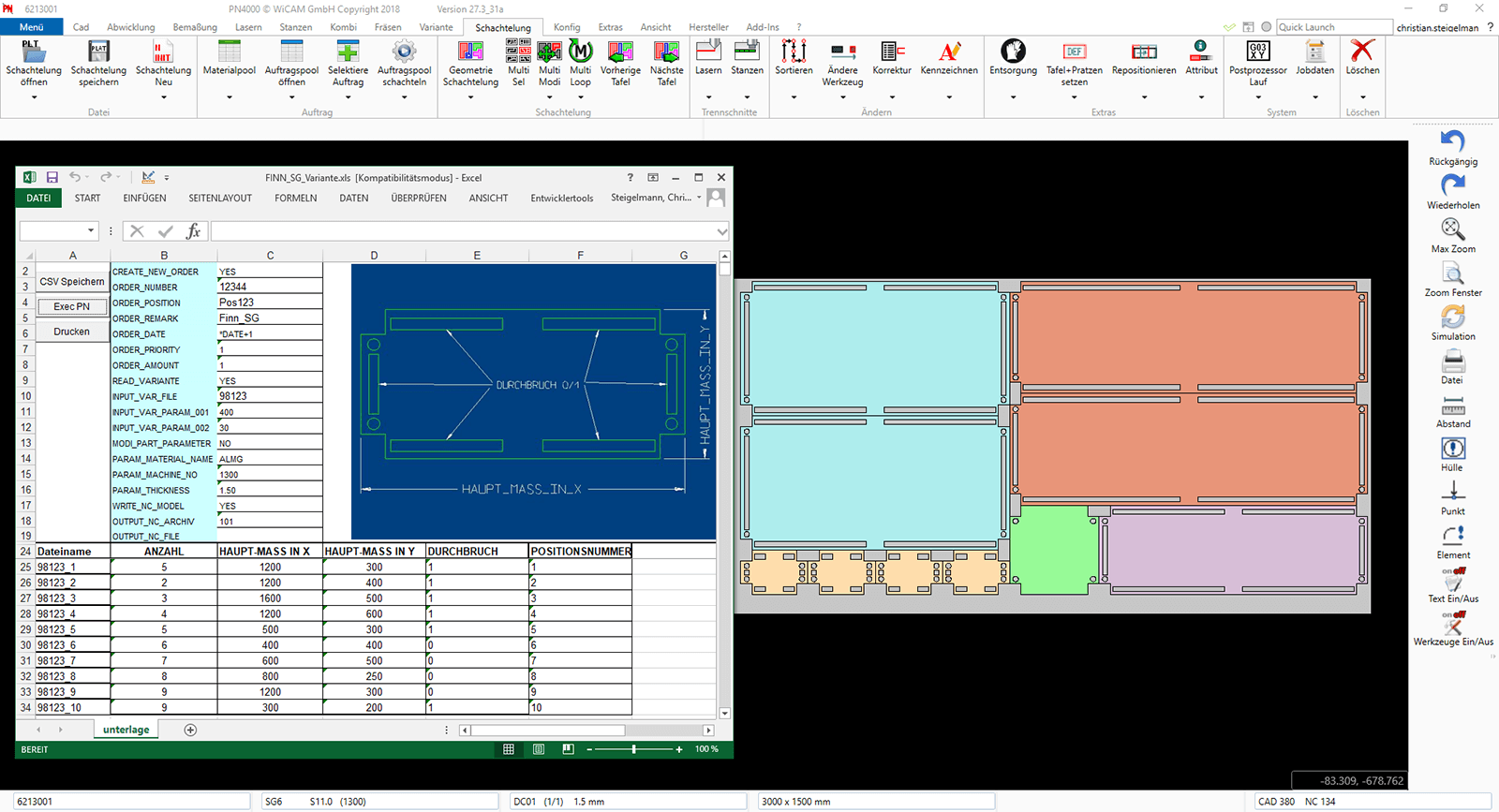

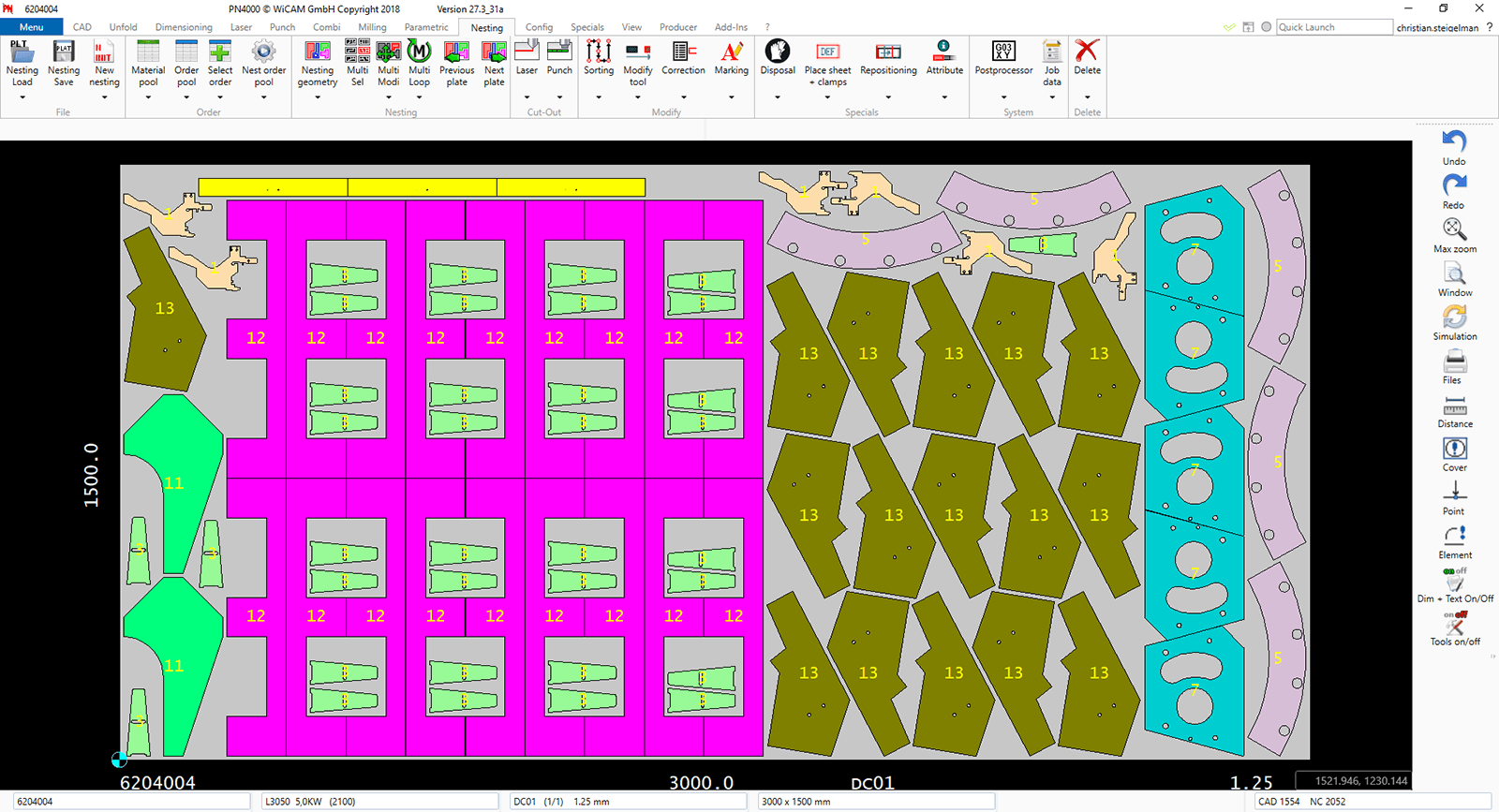

PN4000 is the CAD / CAM / Nesting system for PPS / ERP-driven programming of CNC cutting, punching and portal milling machines of all kinds. The various modules and interfaces enable flexible job shop manufacturing, up to unmanned fully automated, industrial process chains.

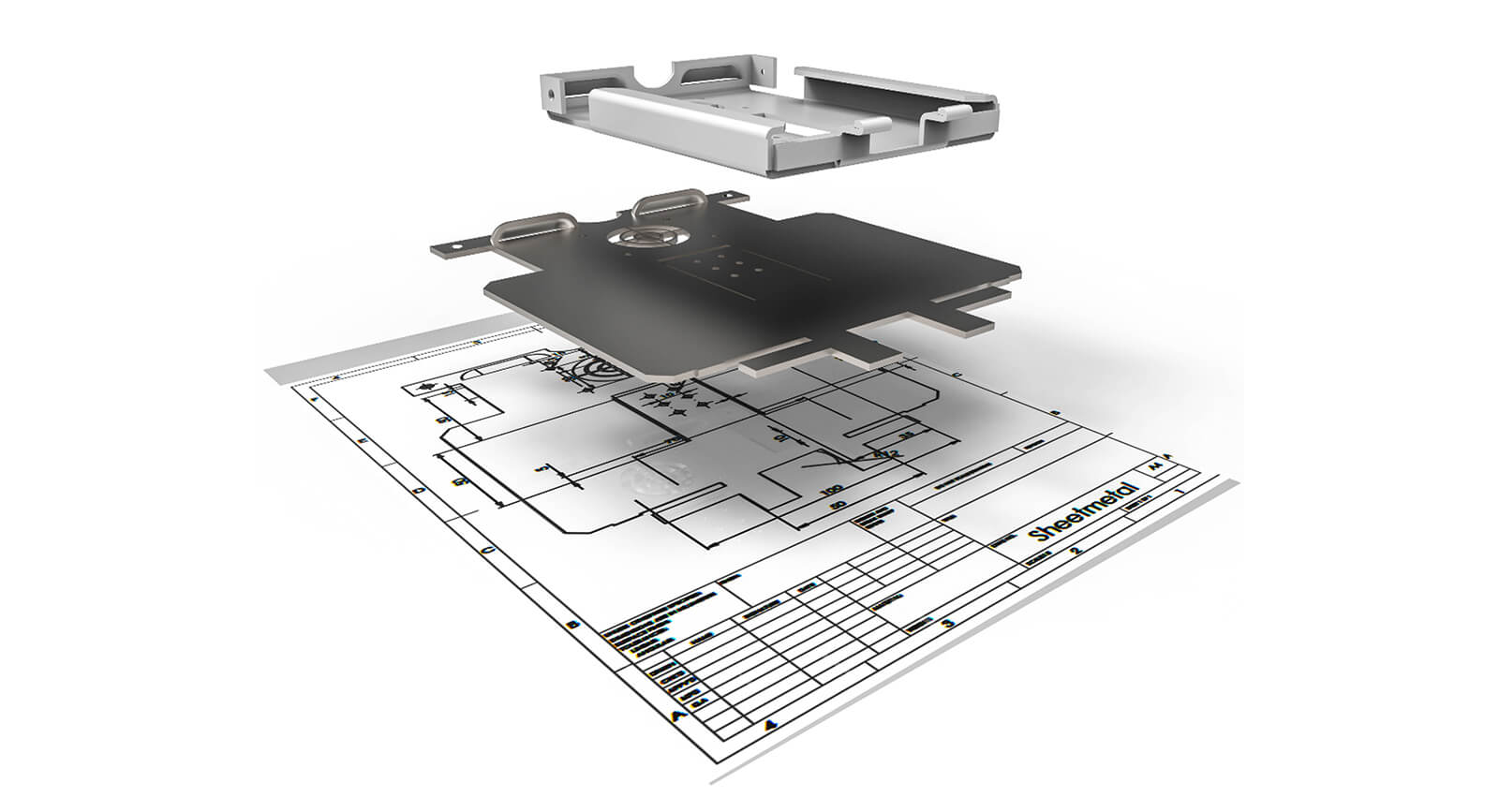

PN4000 is the CAD / CAM / Nesting system for PPS / ERP-driven programming of CNC cutting, punching and portal milling machines of all kinds. The various modules and interfaces enable flexible job shop manufacturing, up to unmanned fully automated, industrial process chains. From the finished assembly to the production-ready DXF file, the data sets must pass through several process steps. With our integrated bending simulation, we offer you a manufacturer-independent complete solution. This eliminates all interfaces between 3D and 2D. Our software solution generates the nesting, the unwinding and the finished bending programme from your parts in one interface – fully automatically ERP-controlled if required.

From the finished assembly to the production-ready DXF file, the data sets must pass through several process steps. With our integrated bending simulation, we offer you a manufacturer-independent complete solution. This eliminates all interfaces between 3D and 2D. Our software solution generates the nesting, the unwinding and the finished bending programme from your parts in one interface – fully automatically ERP-controlled if required.

Every modern production has its own philosophies, production methods and production steps. Since the first program line, we pay particular attention to these individual needs and ensure the integration into the automatic programming process. Together with our customers, we have proven over the last decades with thousands of solutions: not possible does not exist.

Every modern production has its own philosophies, production methods and production steps. Since the first program line, we pay particular attention to these individual needs and ensure the integration into the automatic programming process. Together with our customers, we have proven over the last decades with thousands of solutions: not possible does not exist.