Story:

With a workforce of almost 300, the family-run company KUIPERS CNC Blechtechnik in Meppen, Northern Germany, is one of the largest privately owned job shops in the country. It serves all areas of industrial production, including agricultural machinery, mechanical and vehicle engineering and regenerative energies. Three Stopa storage systems, each around 120 m long and with more than 1,500 storage bins, feed up to 4,500 tons of raw material to the 16 automated CNC punch, laser and combination machines.

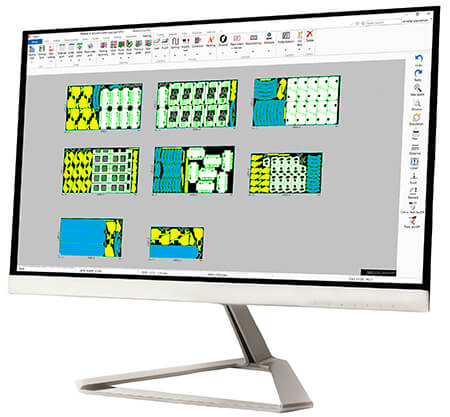

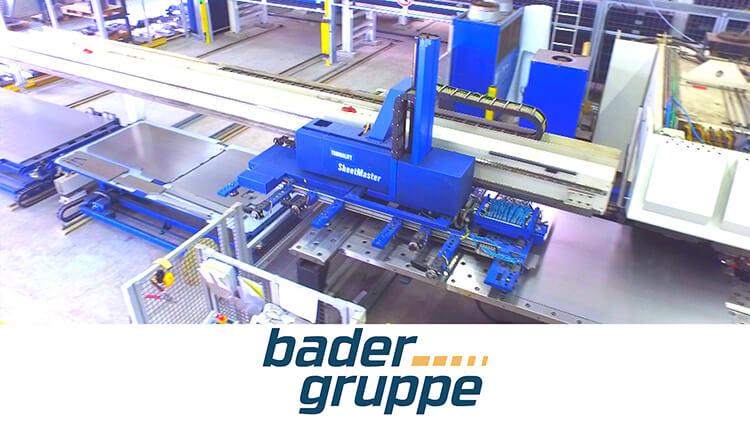

The full range includes a TruMatic 7000FMC, six kilowatt-CO2 single and 7040 double head laser machines, plus several state-of-the-art TruLaser 5040 fiber machines, in other words all top models by Trumpf in Ditzingen, Germany. This production area is programmed entirely by WiCAM PN4000. In the late 1980s KUIPERS purchased its first CNC punch/nibble and laser machines. This was when Wilhelm Kuipers, the third-generation owner of the company, recognized the opportunities of this technology. As the machine fleet grew in the 1990s, it became increasingly clear that the multitude of machines operating on a shift basis would only develop their full potential inside a network that included sales, order management and production.

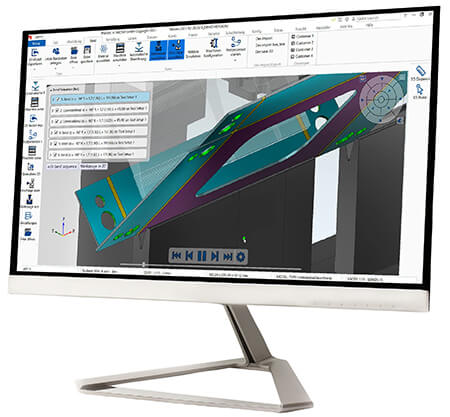

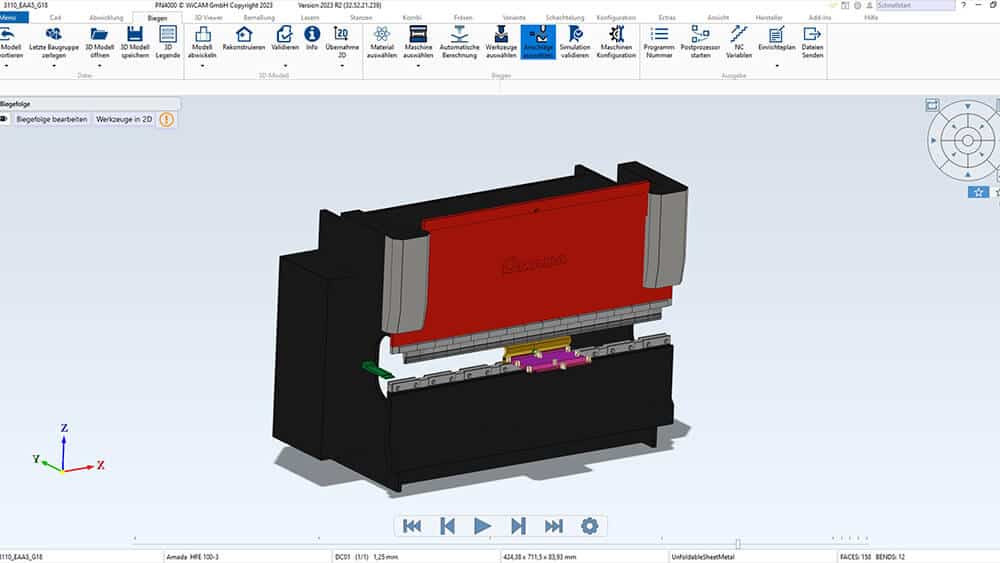

As Wilhelm Kuipers comments, “Having tried out a number of CADCAM systems, we worked out exactly what we wanted. A solution that was quick and simple and able to support all current and future machines, one that could interface with our ERP, enable automation, and allow us to develop our own ideas.” A partner company recommended WiCAM – and Wilhelm Kuipers decided in 2003 to install PN4000 to manage the company’s fleet of sheet metal processing machines. It became instantly clear that WiCAM’s solutions were not just able to precisely control a whole range of technologies, automation components and special machine functions, but also to programme special production processes such as fully automatic wheeling, tapping, flycutting, common line cutting and succer unloading.

The simple, intuitive user interface and the excellent personal support by WiCAM’s local support staff convinced the production planning staff too – Within just a few weeks all CADCAM programmers began to use PN4000 for programming. Looking back, the decision to partner with WiCAM was a major milestone on KUIPERS’ way to the top of its league. Very quickly, administration, production planning, production and logistics were networked so that the data from PN4000 could be made available for pre-calculation and for production alike. When an order comes in, the ERP application Abas informs PN4000 of the parts that have to be produced and seconds later, after real-time nesting, is updated with the current production status and, at regular intervals, the data needed for actual costing. As Michael Kuipers says, In the last decade we’ve again grown tremendously. There is no way we could produce economically on this level without a powerful, flexible software.