Please use our website in portrait format.

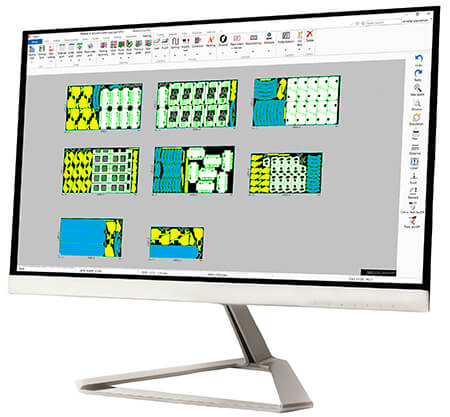

CAD/CAM System

PN4000

CAD/CAM System for ERP/PPS controlled CNC cutting, punching, shearing, milling and combined machining – manual to fully automatic.

Order Control

PNControl

Order management, detailed planning, production feedback and monitoring of deadlines and production.

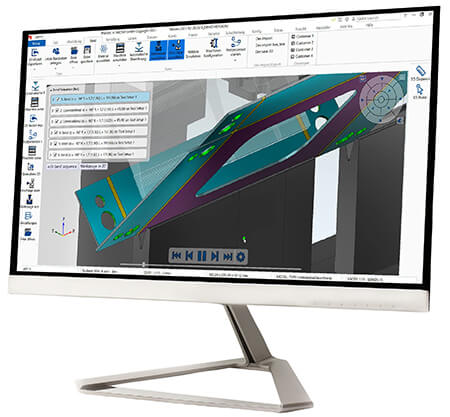

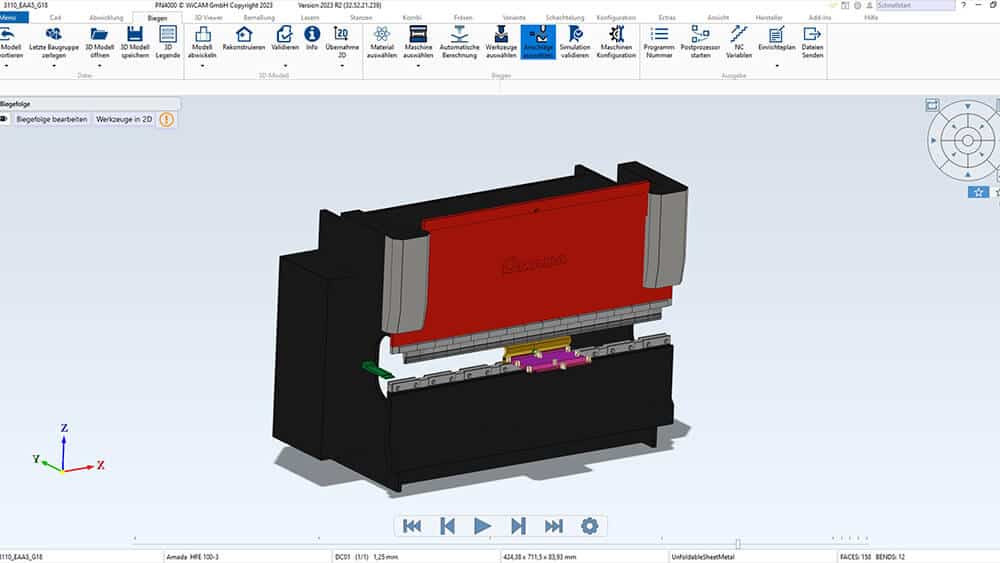

Bend Simulation

PNBend

Unfolding, bend simulation and offline programming of CNC press brakes from various manufacturers.

Calculation

PNCalculate

Online unfolding, calculation, CAD and NC format conversion, parametric component creation.

Training

Well developed and motivated employees are an important element in the daily competition.

Development

We develop new solutions to the very specific requirements for you.

Downloads

For our customers we offer updates and more files online.

Dennis Weisel, the managing director of Metallbau Weisel has always been willing to invest in the future. When he moved his company, including production, to a new hall in Gau-Algesheim near Mainz in 2019, he decided to generate the electricity for his production facility himself. As a result, the entire hall roof is now equipped with a 164 kW photovoltaic system. With the self-generated energy, the company now produces stairs, canopies, railings and much more. Surplus electricity is fed into the grid.

Dennis Weisel, the managing director of Metallbau Weisel has always been willing to invest in the future. When he moved his company, including production, to a new hall in Gau-Algesheim near Mainz in 2019, he decided to generate the electricity for his production facility himself. As a result, the entire hall roof is now equipped with a 164 kW photovoltaic system. With the self-generated energy, the company now produces stairs, canopies, railings and much more. Surplus electricity is fed into the grid.

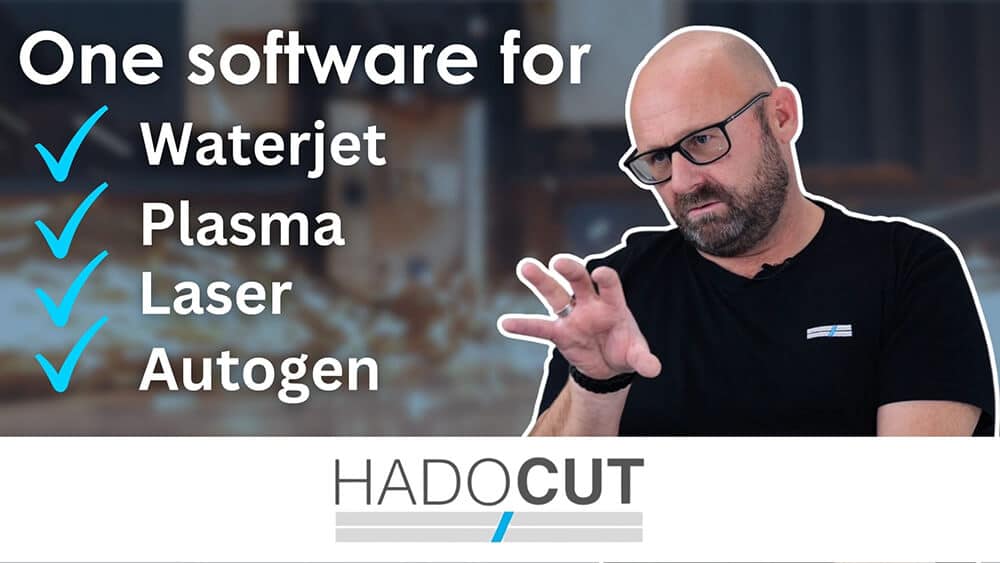

With the decision, the question of a suitable programming system which offers flexibility for the future and can integrate further technologies such as bending” arose at the same time. Mr. Kunz then invited Mr. Weisel to Xteg’s annual Fiber Days, where he had the opportunity to meet all of Xteg’s partners in person. One of them was and still is the software house WiCAM, located near Karlsruhe, which offers Xteg customers a manufacturer-independent CAD/CAM system for controlling their MARVEL fiber laser system as well as all common other manufacturers.

With the decision, the question of a suitable programming system which offers flexibility for the future and can integrate further technologies such as bending” arose at the same time. Mr. Kunz then invited Mr. Weisel to Xteg’s annual Fiber Days, where he had the opportunity to meet all of Xteg’s partners in person. One of them was and still is the software house WiCAM, located near Karlsruhe, which offers Xteg customers a manufacturer-independent CAD/CAM system for controlling their MARVEL fiber laser system as well as all common other manufacturers.