WiCAM at Blechexpo 2025

News, 22. July 2025

From 21 to 24 October 2025, WiCAM will be presenting its current range of CAD/CAM/Nesting/Bending/Cloud software for the sheet metal processing industry at Stand 1301 in Hall 1.

From 21 to 24 October 2025, WiCAM will be presenting its current range of CAD/CAM/Nesting/Bending/Cloud software for the sheet metal processing industry at Stand 1301 in Hall 1.

The latest development stages of the PN product series for ERP-integrated fully automatic programming and process control of all types of CNC punching, laser, water, flame cutting, slicing, bending and combination machines will be on display.

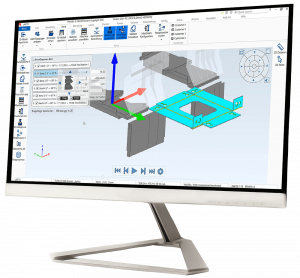

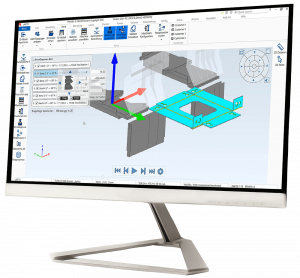

In addition to hundreds of detailed improvements and new PPS/ERP interfaces, we are presenting the latest PN4000 version with complete 3D integration. This includes a fully integrated bending simulation that reads and processes 3D formats such as STEP directly / fully automatically.

Highlights at our trade fair stand

PNBend Update | Automatic bending sequence optimised

PNBend Update | Automatic bending sequence optimised

In the latest version of PNBend, a software module of PN4000, several significant enhancements have been added that further optimise the programming and bending process.

By updating the calculation of the bending sequence, you can reduce the number of tools required in many cases and in some cases save over 50 % of the set-up time on the machine – which significantly increases efficiency.

It is now also possible to have an automatic bending sequence calculation performed for very complex components.

PN4000 | Power Nesting Update | Optimise NC programs

WiCAM’s latest update gives the Power Nester many ‘Quality of Life’ improvements for a high level of nesting efficiency.

Thanks to new parameters, the Power Nester can significantly reduce the number of panels and NC programmes. As fibre lasers become ever faster, the efficient clearing of parts is becoming an increasingly relevant factor. Our new version has algorithms that reduce various NC programmes with just a click, ensuring maximum material utilisation.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information

Our PN4000 programming system and the power nesting routine are manufacturer-independent. While you can control your production manually or directly from your ERP system, it doesn’t matter whether you have a Trumpf TruLaser, Bystronic laser system, LVD laser system, Amada laser system or another CNC machine. With WiCAM you can control all manufacturers.

PNCalculate | New version | Calculation incl. bending simulation

PNCalculate | New version | Calculation incl. bending simulation

We have divided our cloud-based calculation solutions into 3 product areas: internal calculation, webshop solution and the universal tool – our API interface.

The latest version of PNCalculate has been updated with a new interface and some important improvements to enable even more accurate calculation of production prices for sheet metal components in the future. When uploading, a feasibility check and a bending simulation are generated immediately, allowing you to check directly in the browser whether and how the part can be produced. This allows you to create even more accurate quotations for your customers.

Major industry players such as Laserhub, Suplacon and many others have been relying on our API interface for years. The parts are transferred to our servers via interfaces and we determine all production steps in seconds – the ideal way to carry out sales prices, marginal cost calculations and feasibility studies.

Make an appointment now!

Blechexpo takes place in 70629 Stuttgart.

Please send your appointment request for a personal meeting at the trade fair to Mr. Maximilian Herz via our contact form.

Date

21.10. – 24.10.2025 | daily from 09:00 am – 5:00 pm

Our stand

Hall 1 | Stand 1301

Directions

Messepiazza 1, 70629 Stuttgart, Germany

BOOK AN APPOINTMENT NOW!

From 21 to 24 October 2025, WiCAM will be presenting its current range of CAD/CAM/Nesting/Bending/Cloud software for the sheet metal processing industry at Stand 1301 in Hall 1.

From 21 to 24 October 2025, WiCAM will be presenting its current range of CAD/CAM/Nesting/Bending/Cloud software for the sheet metal processing industry at Stand 1301 in Hall 1. PNBend Update | Automatic bending sequence optimised

PNBend Update | Automatic bending sequence optimised PNCalculate | New version | Calculation incl. bending simulation

PNCalculate | New version | Calculation incl. bending simulation