Apfel GmbH has been programming with the WiCAM CAD/CAM system since 1999

News, 17. September 2025

Apfel GmbH, based in Dossenheim near Heidelberg, has been creating professional factory equipment for the metal industry for over 30 years. High-quality tool cabinets, mobile storage cabinets, and storage tower solutions are the spearhead of its product portfolio. To optimally control its production processes, Apfel has been using the PN4000 programming system from WiCAM GmbH since 1999.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information

The Beginnings: Founding and Transformation

Stefan Apfel founded the company in 1988, starting out as an agricultural machinery mechanic. As a supplier with an extended workbench for larger companies, Stefan Apfel had already kept his eye on the future and transformed Apfel GmbH from a pure supplier to a production facility for storage systems in the metal industry.

With the changing manufacturing processes resulting from the reorientation in mind, the key question ultimately arose as to how Apfel GmbH could optimally position itself for the future:

“Then we looked at who was available on the market, sought advice, and that was the step that made us realize we needed software that would accompany us into the future.”

Stefan Apfel, Managing Director of Apfel GmbH

Investing in the Future

When you introduce a new technology these days, the software must also grow with it. And that was the key reason why Apfel ultimately chose the PN4000 software solution from WiCAM.

Together with Mr. Wilkesmann, the founder of the WiCAM group of companies, the goal of being able to control sheet metal production machines with PN4000 regardless of the manufacturer was achieved.

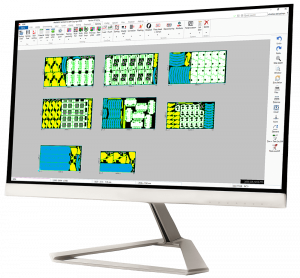

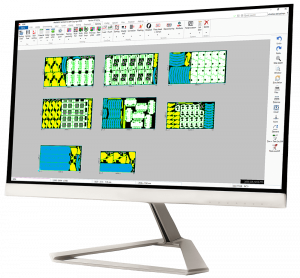

The 3D designs are drawn in SolidWorks and transferred to WiCAM for processing. Nesting is also very important here to ensure optimal use of the sheet metal panels. A maximum material waste of 10% was determined here.

Another step towards the future: The PN4000 update

With the growth of Apfel GmbH and the introduction of new technologies, investments in large machines are necessary. This was the moment when it became clear that the PN4000 programming system from WiCAM also needed to scale.

The new PN4000 update allows Apfel GmbH, for the first time, to add multiple customers to a single sheet and process an entire order pool. The more efficient use of sheet metal is particularly noticeable, as individual customers no longer need to be processed on a single sheet.

Apfel GmbH programs a knife laser system, a Trumpf TLC1005, and a Trumpf TruMatic TC6000 with LiftMaster using the PN4000 programming system from WiCAM.

The programming system offers the ideal interface for achieving consistency. Whether old or new machines, the main reasons for the update are speed, adaptability, and the ability for every employee to control the software.

Schedule an online demo now

Schedule a personal consultation or live demo now and discover the possibilities of the latest PN4000 version – including optional modules such as 3D processing and power nesting. Whether updating, expanding, or starting a new business: We’ll support you from the first step to successful implementation.

Schedule an online demo