Historia:

As an innovator in the area of CNC sheet metal and pipe processing, the Dutch company De Cromvoirtse is known across Europe. With unmanned storage / sorting systems and state-of-the-art production equipment from different manufacturers, De Cromvoirtse has fully automated all areas of production.

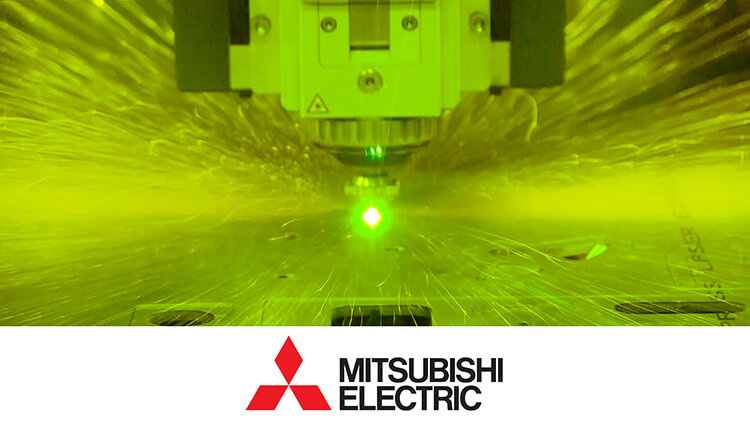

Since 2005 the predominant part of the production is controlled with WiCAM PN4000. Janwillem Verschuuren, co-owner and managing director, gives a brief insight into the history and the processes of his company: Our first CNC lasers in the 90s were from Esab, followed by models from Trumpf.

We have operated with the supplied programming system. It became complicated when we wanted to combine other machines, warehouse and ERP systems from other manufacturers automatically. After the first presentation of the PN4000 I knew – that’s it.

It is uncomplicated and has loads of postprocessors and interfaces in all areas. For requests, for which there were no available solutions, we could order special developments – or we developed, as for example our web shop, own moduls – and linkings.

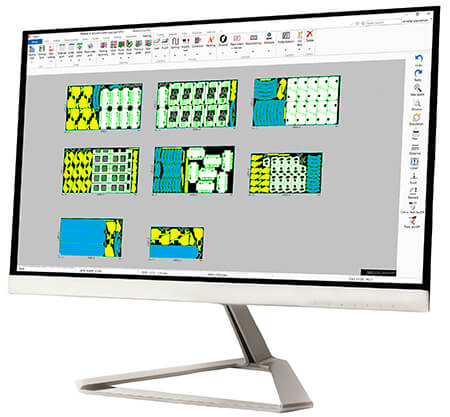

When De Cromvoirtse went online with the web shop 2008, the company was thus one of the pioneers of the industry. The initially sparse inquiries have developed into a firm size of business operations. In the beginning, the parts were calculated individually. Later, the algorithms for determining more accurate prices were converted to nesting-based partial calculation. Today, PN4000 together with the ERP system, delivers real-time calculation data for the web shop for up to 2500 offers per day.

For business partners who want to outsource their production, De Cromvoirtse offers online direct interfaces for external ERP systems. Janwillem Verschuuren: ,This means that our large customers can calculate any order volumes centrally and schedule them on a day-to-day basis. As a result we have a reliable pre-planning for orderings and production. For online price calculation for pipe sections and for waste optimization of the manual shear, De Cromvoirtse also uses modules of the PN4000.

For the material disposition, the material warehouse and remnant management of the PN4000 are linked to the ERP system and to the Kasto storage system Uniline 3.0. Remnants are automatically generated and used as soon as suitable parts can be nested with favorable cutting values.

Janwillem Verschuuren: In this way, we save material, keep our inventory low, and always have accurate data for pre- and post-calculation as well as future material orders. Since the beginning of the year, a new Bystronic Bysprint Fiber with 6 kw combined with a fully automatic Astes4Sort loading and sorting unit has been supporting the existing machine park.

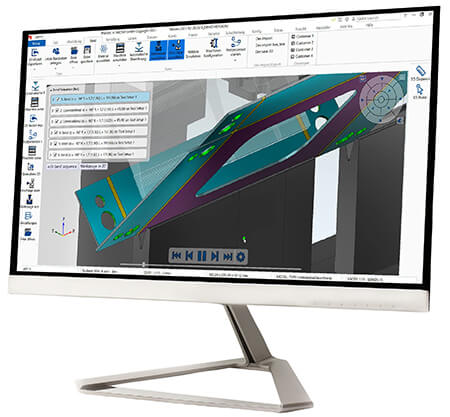

The necessary production data and feedback messages are also exchanged via an interface in PN4000. De Cromvoirtse is supported by WiCAM Benelux, who are dedicated to providing interfaces and support requests in the day-to-day business with great commitment and creative solutions.

Janwillem Verschuuren: Integrated into our ERP system and our web shop, PN4000 controls our complete production according to the utilization up to 24 hours on 7 days per week. The communication between the IT systems and our production also runs around the clock fully automatically. For the few remaining special cases we still need a half CADCAM programming place of work in the day shift.