Please use our website in portrait format.

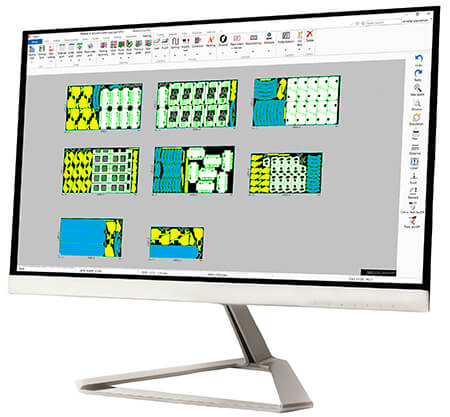

System CAD/CAM

PN4000

Kompleksowe rozwiązanie do cięcia (laser, autogenny / plazma, strumieniem wody) wykrawania oraz procesów mieszanych.

Kontrola Zamówienia

PNControl

Narzędzie do szczegółowego planowania, kontroli zamówień, realizacji i obserwacji produkcji, zgodnie z planem produkcji.

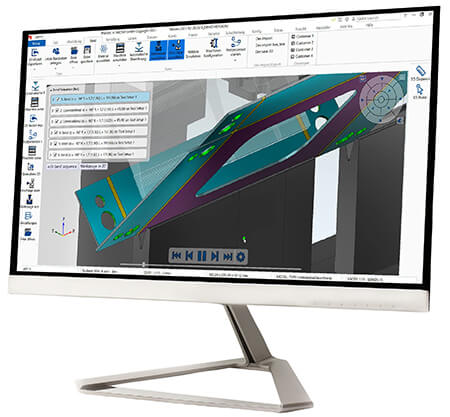

Zaginanie

PNBend

PNBend tworzy rozwinięcia z modeli 3D i generuje kompletne programy gięcia od nich.

Obliczenia

PNCalculate

Rozwijanie online, obliczanie, konwersja formatu CAD i NC, tworzenie parametrycznych komponentów.

Szkolenia

Dobrze przeszkoleni i zmotywowani pracownicy to klucz do sukcesu w biznesie. Te szkolenia,

Programowanie specjalne

Tworzymy nowe rozwiązania pod bardzo specyficzne wymagania klienta.

Pobieranie

Dla naszych klientów oferujemy aktualizacje on-line oraz możliwość pobrania innych plików.