Historia:

The Bader Group is a market leader in the development, design and production of machine housings, switch cabinets, custom-made enclosures and special-purpose tanks, employing 950 staff in five locations across Germany and Hungary.

Tobias Höhnlein is Production Manager at the site in Senden, Germany. As he says, Baden’s customers expect rapid and precise solutions for complex projects – often in connection with large order volumes and ever smaller batches. To meet these apparently conflicting requirements, in 2014 the Bader Group invested in a new cutting center. At the Senden site, automated punching, punching lasers and laser machines by Trumpf operate next to a centralized Stopa warehouse.

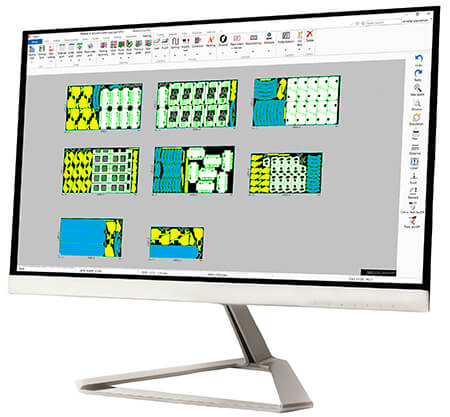

When the new cutting center went into operation, OEM system programming quickly reached its limits. For one, existing parts had to be re-created for the new machines. For another, the number of additional parts to be programmed increased due to greater product diversity. After an in-depth market analysis, WiCAM was judged to offer the best overall solutions PN4000 was installed to control the machines and handling systems.

PNControl was implemented for order allocation, capacity utilization control and evaluation of machine feedback messages. From Day 1, the machines and the storage system ran on WiCAM. Just a few weeks later, all production information from the PPS system to the finished assemblies had been collated.

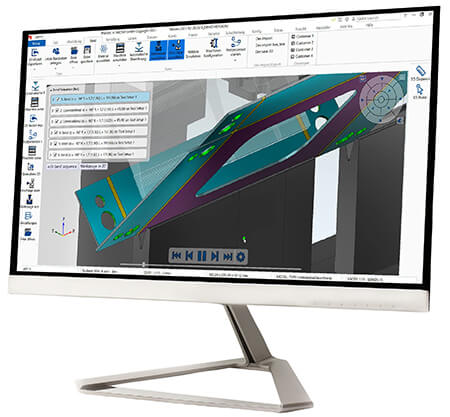

The 3D CAD data are automatically enriched with cutting and machining information and transmitted in XML format via the 'SolidWorks add on SPI’. Using the automatically engraved part numbers from the PPS system, each component produced can later be identified precisely. The machine housings, one of the main products of the Bader Group, often consist of up to 400 different individual components each with different sheet thicknesses. For optimal material utilization and production scheduling, different orders are produced using the same sheet.

To remove any potential for error and speed up the logistics, WiCAM teamed up with Bader to develop PNCleanUp. The software shows the produced nestings on the clearing table and tags different jobs and assemblies with different colors so no confusion can ensue. To this end, PNCleanUp uses information generated by the other PN products, the PPS system, and machine feedback messages.

In addition, the software notifies the PPS system of the sorted parts to trigger further processing. In spring 2017, the PN products were also installed at the Wachau plant near Dresden in Germany, where Bader uses machines by Amada and Bystronic for punching and lasering. The work preparation lines at the various sites were now able to exchange production plans, and create mixed production lists of third-party and in-house orders at the click of a mouse.

WiCAM’s PN products have paid off in the shortest possible time. They enable Bader to engage in cross-plant capacity planning and frees up capacity for innovations and further growth.