Please use our website in portrait format.

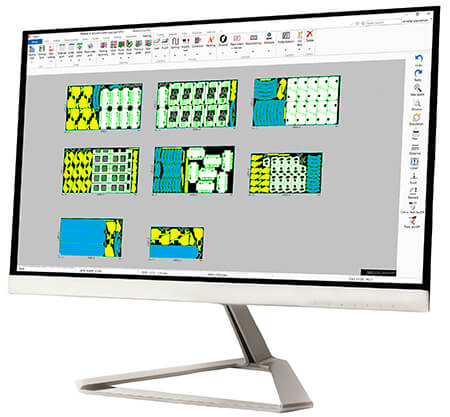

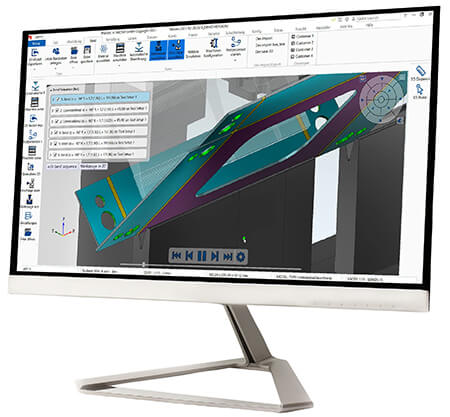

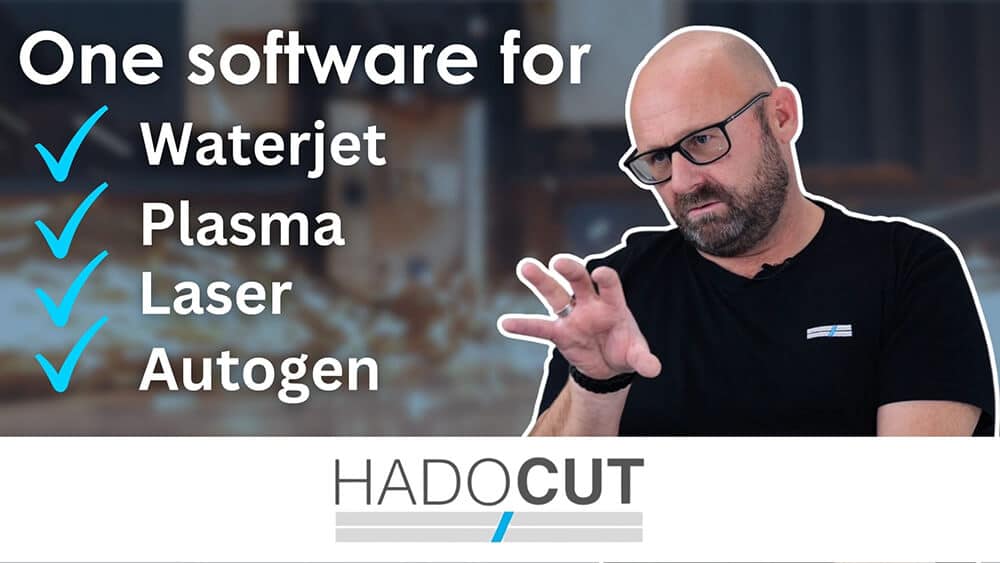

CAD/CAM-systeem

PN4000

De totaaloplossing voor snijdende machines (Laser, Autogeen / Plasma, waterstraal), ponsnibbelmachine en combi-machines.

Ordermanagement

PNControl

Hiermee is mogelijk om een detailplanning over verschillende machines uit te voeren.

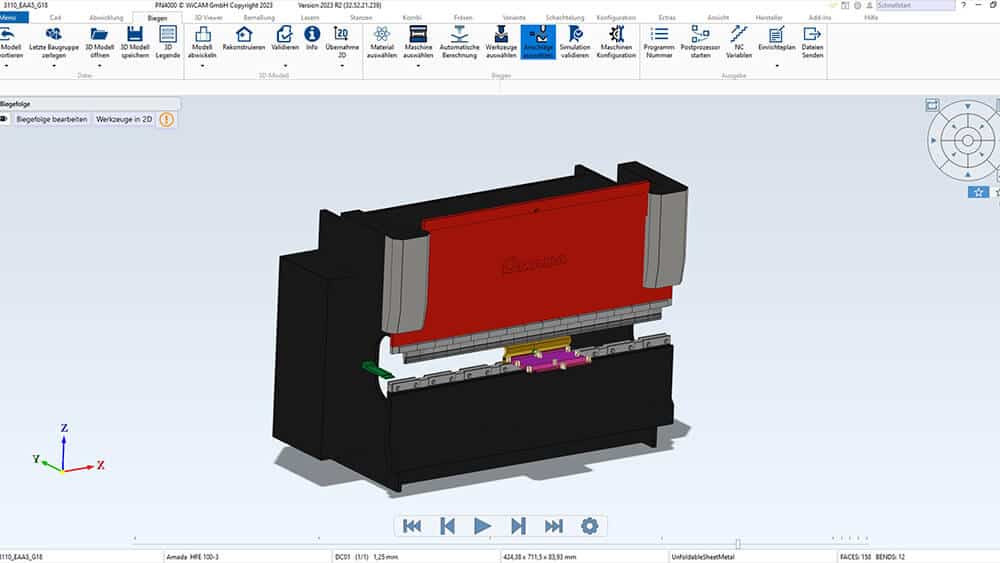

Buigen

PNBend

Met PNBend is mogelijk om uitslagen te genereren van aangeleverde 3D geometrie.

Calculatie

PNCalculate

Zo kan bijvoorbeeld op eenvoudige wijze CAD geometrie van het ene in het andere formaat geconverteerd worden zonder dat u in dure CAD software hoeft te investeren.

Opleidingscentrum

Haal de kennis van WiCAM software in huis en investeer in je eigen medewerkers en bedrijf.

Software ontwikkeling

We ontwikkelen nieuwe oplossingen om aan je specifieke behoefte te voldoen.

Downloads

Updates en installatie bestanden zijn te downloaden voor klanten met een service en onderhoudscontract.